Let’s discuss the question: how to change mechanical seal in centrifugal pump. We summarize all relevant answers in section Q&A of website Bmxracingthailand.com in category: Blog technology. See more related questions in the comments below.

When replacing a mechanical seal on a pump it is important?

- It is I, Inspector Pumphead! …

- The main purpose of the mechanical seal is to prevent leakage. …

- The first step of replacing your seal, is to make sure the power to your pump is off because safety is always the first step.

What is mechanical seal in centrifugal pump?

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

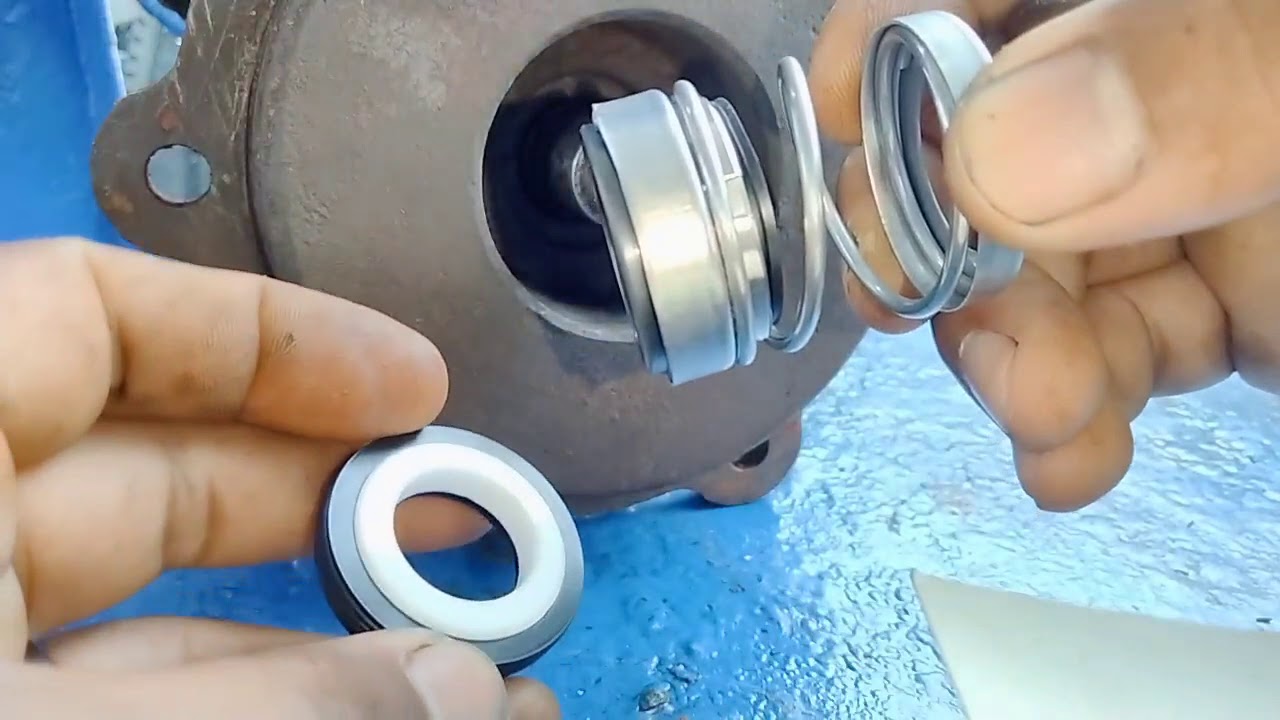

how to replace mechanical seal in water pump

Images related to the topichow to replace mechanical seal in water pump

When should I replace my mechanical seal?

The most obvious indicator that the mechanical seal on your equipment needs to be repaired or replaced is a spraying leak. If water is spraying by the shaft seal, there is definitely a need to have the mechanical seal checked out.

How does a mechanical seal work on a pump?

A mechanical seal works by having two very flat (generally within 2-3 light bands flat) lapped flat faces. This allows a shaft to turn while maintaining a seal. It is very difficult for leakage to occur (beyond a vapor) if installed properly and in good condition.

How do I order a mechanical seal?

On the back side of the “seal head” (the end which fits towards the “spring”), measure the inside diameter. This will determine the seal size diameter – which is either the shaft size or the sleeve size that the seal fits over. The front side of the seal usually has a black carbon face.

Can you reuse a mechanical seal?

Reassembly. Once the components have been checked to be acceptable for reuse, they can be reassembled and reinstalled in the pump in accordance with manufacturers’ recommended procedures.

Centrifugal Pump Seals – Mechanical Seal Installation

Images related to the topicCentrifugal Pump Seals – Mechanical Seal Installation

How do you know if a mechanical seal has failed?

- Grooves or notches on the seal. …

- Squealing or popping sound. …

- Uneven wear track. …

- Fractured or cracked seal face. …

- A cracked or chipped seal ring. …

- An accumulation of carbon dust on the outside of the seal.

How long does a mechanical seal last?

Most seal manufacturers say that operation of the seal at one of these limits will result in a minimum life span of two years; three years with some seal types such as those specified in Standard API 682.

What are the parts of mechanical seal?

- One ring (usually the seal face) circulating synchronously with the rotating part (shaft)

- Secondary seal (usually O-ring) between shaft and ring.

- A stationary ring (usually the stationary seat) arranged in the stationary part (casing)

Where is mechanical seal in pump?

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an o-ring or gasket clamped between the stationary part and the pump housing. The rotary portion of the seal is sealed onto the shaft usually with an O ring.

PAANO IKABIT ANG MECHANICAL SEAL | HOW TO INSTALL MECHANICAL SEAL

Images related to the topicPAANO IKABIT ANG MECHANICAL SEAL | HOW TO INSTALL MECHANICAL SEAL

Do you lubricate mechanical seals?

Lubrication is necessary for proper mechanical seal installation. Lack thereof can damage o-rings or rubber bellows on the seal, causing them to tear, or roll.

What causes mechanical seal failure?

A mechanical seal might fail due to poor lubrication, or no lubrication at all. When there is no liquid around the seal it will be subjected to increased amounts of friction which will increase the temperature inside the pump.

Related searches

- how to install a mechanical seal on a centrifugal pump

- how mechanical seal works

- how to replace mechanical seal in centrifugal pump

- mechanical pump seal installation

- centrifugal pump mechanical seal leaking

- Mechanical seal

- pump seal replacement

- centrifugal pump seal

- how to repair mechanical seal

- water pump seal change

- mechanical seal used in centrifugal pump

- How mechanical seal works

- mechanical seal

Information related to the topic how to change mechanical seal in centrifugal pump

Here are the search results of the thread how to change mechanical seal in centrifugal pump from Bing. You can read more if you want.

You have just come across an article on the topic how to change mechanical seal in centrifugal pump. If you found this article useful, please share it. Thank you very much.